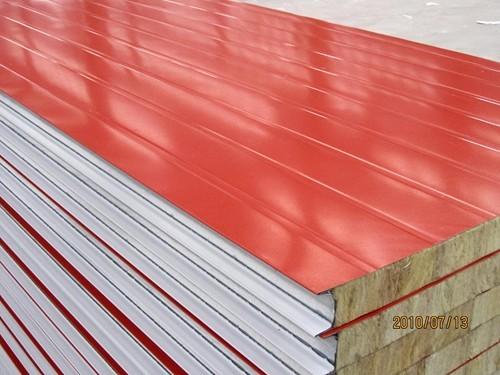

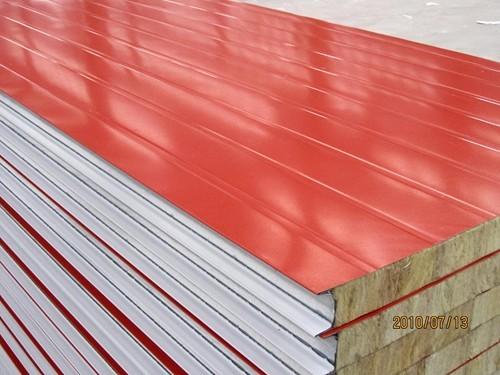

metal rock wool sandwich wall panel roof panel

$10/m

KRS Sandwich Panels consist of an insulation core with facings of flexible materials and are produced on a continuous laminating line using a two part polyurethane adhesive system. They are used in the building of insulated structures such as coldrooms, classrooms, distribution centers, freezers and abattoirs.

The core materials that can be used are expanded polystyrene (EPS), Rock wool, PU/PIC, POLYPHEN and extruded polystyrene (XPS).

The facing materials are pre-painted galvanized steel, Aluminum or GRP.

The standard width of panels is 950mm, 970mm, 1000mm and 1150mm.

Panels can be manufactured to any transportable length.

The panels have a male female INTA lock system and various face profiles can be produced. The profiles included are: flat, fluted, shadow line, micro rib and raised rib.

Advantages and Disadvantages of the different core materials

EPS Core Panel

Advantages

It is the most economic form of insulation

It is extensively used due to its insulation properties and high strength to weight ratio

It has a high resistance to water absorption

The flexible core is not easily damaged

Its relative low weight makes panel installation an easy process

Disadvantages

When exposed to a fire the core material starts softening from 90̊ C and the panels lose their structural integrity

The core material ignites at 350̊ C in air

Rock wool Core Panel

Advantages

It has excellent thermal and acoustic properties

It is fire safe

It is chemically inert and CFC and HCFC free

Disadvantages

The price is higher

The panels are fragile and need to be handled carefully

The panels can delaminate with dynamic loading of excessive foot traffic

The core materials are imported which adds 8 weeks lead time to the start of installation

The high panel weight requires mechanical equipment for installation

| Industry Category | Construction-Real-Estate/Multifunctional-Materials |

|---|---|

| Product Category | |

| Brand: | krs |

| Spec: | 890 |

| Stock: | |

| Origin: |