PET sheet extrusion machine PET sheet making line

37500

- PET sheet extrusion machinePET sheet making line

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Application: Thermoforming(cup, bowel, etc. ), food box, fruit/egg tray, cup, electric tray, stationery, printing sheet, packaging, etc.

It used co-extrusion technology produce multi-layer co-extruded PET sheet, such as APET/PETG, PETG/APET/PETG, APET/RPET/APET. It widely used in attracts models packing, printing, elec. Packaging and etc. With precision dispenser, sheet layered evenly, each layer thickness adjustable.

The screw to the modular structure, Adapt to the APET production of secondary materials, Also suitable for the PLA production of biodegradable materials. Solve the horizontal corrugated PET sheet production quality defects; (exclusive)!

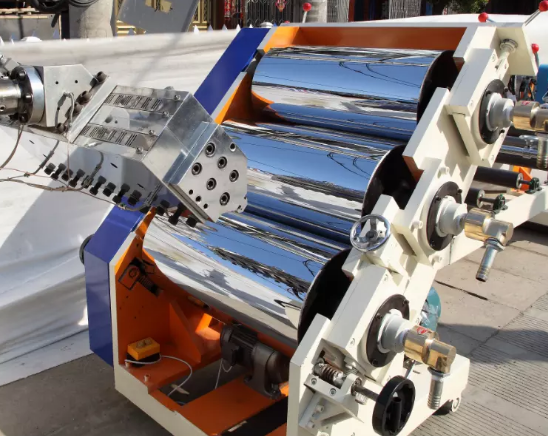

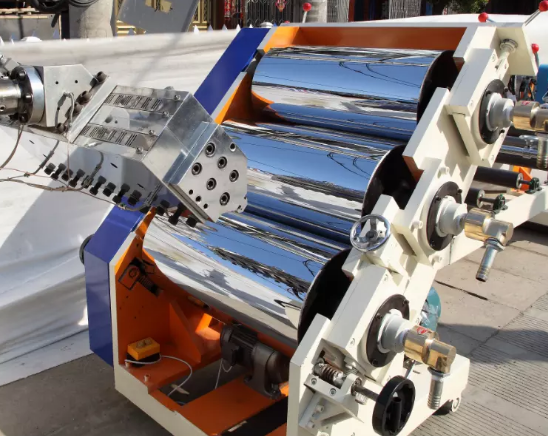

(1)Type of drive :chain drive

(2)Speed adjusting : frequency control

(3)Roller adjusting : adjusting accuracy 0.0125mm

(4)Pressing way:Electric pressing.

(5) Roller structure : twin way

|

(6)Main parameters |

|

|

Roller parameters |

Φ350-750mm*3 |

|

Roller accuracy |

≤0.01mm |

|

Roller surface bright degree |

12degree |

|

Motor power |

4kw |

|

Roller temperature accuracy |

≤±1℃ |

(7)Cutting Configuration

1. Rotation knife , two directions

2.Material direction flexible , each angle adjustable

(8)Cooling rack

1.Delicate structure , easy operation

2.Roller :¢80×800mm

3.Al roller : high quality

(9)Single layer Rewinding machine

(10)Traction equipment

1. Traction form : Plastic roller , another stainless steel

2. Drive form : frequency adjusting

3.Roller pressing : rubber cylinder pressing

4.Hard :A60degree

|

5.Main parameters |

|

|

Rubber roller |

φ205×750mm |

|

Other roller |

φ215×750mm |

|

Motor power |

2.2kw |

: Control System

1.Temperature controlling adopt PID adjusting technology , high quality , the accuracy max.±1℃

2.Extruder motor 55kw -4 level , frequency adjusting control

3.Flexible techonology , Multi control system

4.Circuit board combination structure, module type silicon controlled .

PP, PE ,PS plastic sheet extrusion machine

What this machine can do?

Just put the raw material grain into the Funnel.and via the machine heat and water cooling,then produce the plastic sheet.

Production:

plastic sheet material extruder is composed of extruder,net transducer,die head,calender roller,takein machine,electric controller etc.The operational principle of the unit is as below:According to the tristate change of thermoplastic under different temperatures and take advantage of screw’s push effect,turning physical appearance into high pellet state,and then transform into plastic liquid.After flowing from the mould,then wind in received volumes via pressure-ray cooling stereotypes.The main fratures of this crew as below:feed cylinder,screw and mould are made of high quality alloy structure with the nitrogen.It has high hardnenss,corrosion protection,and long use span. The frame head adopts racks of guns and over.The flowing channel is suitable for the fluxion of liquid,non stagnation phenomena,the thickness of products are homogeneous,the pressure-ray roller adopts big screw shafts.It has excellent effect of adopting water cycle to cool,the temperature of feed cylinder and mould head are controlled by controller separately.The rotational speed of screw,pressure-ray machine rotational speed,rotational speed of received volumes can be adjusted respectively to ensure the speed of the whole set synchronous.

This machine is applicable to the production of ABS,PP PS HIPSPMMA PA POM PP/PE PS EVA sheet environmental protection biological degradation plastic sheet etc.It is widely used for forming of plastic sheet,packaging products,office supplies,antiseptic adhesive tape such as packaging boxes,cup,bowl,salver and so on.

ABS,PP PS HIPSPMMA PA POM PP/PE PS EVA sheet extrusion machinePP,PS sheet making line

| Industry Category | Machinery/Machinery-Processing-Services |

|---|---|

| Product Category | |

| Brand: | Gongle |

| Spec: | GL515 |

| Stock: | |

| Origin: |